Crawler-type self-propelled lifting platform

Classification :

Keywords : Convet Elevator Group

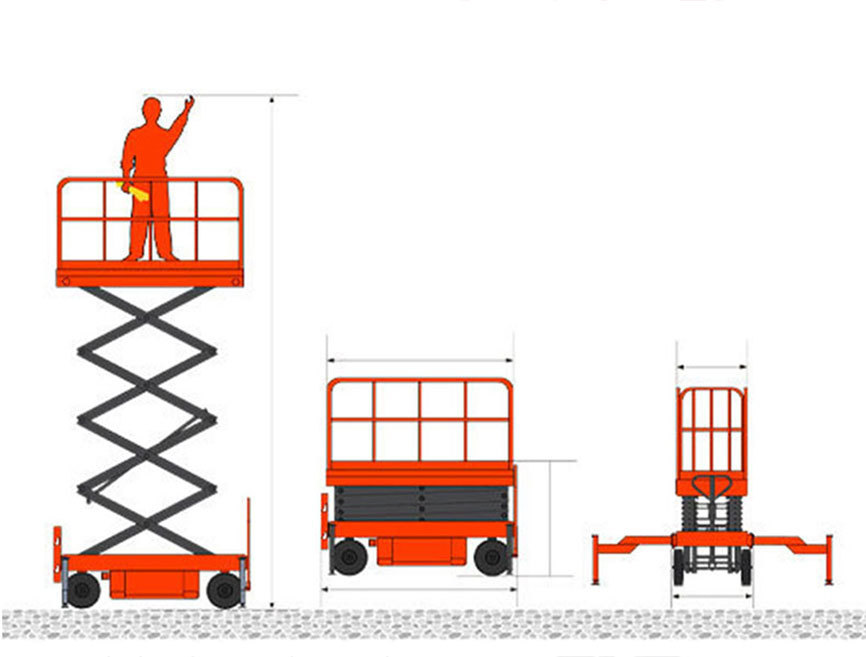

Sscissor Lifting:

The mobile scissor lifting platform is a special equipment for working at heights, that with a wide range of uses. The scissor-type mechanical structure makes the lifting platform have higher stability after lifting. The machine with wide working platform and higher carrying capacity, which make the range of high-altitude work larger and suitable for multiple people to work at the same time. It makes working at heights more efficient and safer.According to the customers feedback.

Mobile scissor lifting platform application:

The mobile scissor lifting platform is a special equipment for working at heights, that with a wide range of uses. The scissor-type mechanical structure makes the lifting platform have higher stability after lifting. The machine with wide working platform and higher carrying capacity, which make the range of high-altitude work larger and suitable for multiple people to work at the same time. It makes working at heights more efficient and safer.

Mobile scissors are mainly used in various fields such as street lamp installation and maintenance, advertising installation, photography, garden work, indoor maintenance, docks, etc.

Advantages of buying:

You'll enjoy the freedom, flexibility and availability of your device when you need it.

You can often benefit from top-of-the-line equipment and new technology. Those who buy directly from a dealer can avoid the need to select alternatives or wait by customizing an order to meet their specific needs.

Advantages and disadvantages of scissor lift rental.

For short-term use of lifts, leasing is a good way to go, and if you only need to use a scissor lift for a few hours, days, or even weeks to get a job done, there's no point in buying it. Take an eight-meter scissor for example, if you only need it for a week, the possible rental price is about USD1,000. If you buy a new machine, you need about 7000USD.

Renting is a time saver, and if you need an extra machine to help get the job done faster, considering renting a scissor lift may be the right choice.

Renting also provides a better understanding of the product's attributes, allows you to choose a machine that is suitable for the height of use, and is the perfect way to try out a new machine before deciding to buy. The renter is generally not responsible for costs such as maintenance, but some may be factored into the final rental price. Either way, you won't have to worry about downtime due to equipment malfunction or failure. You can usually quickly swap your unit for another elevator lease and get back to the job at hand.

Renting allows you to test different models to find the perfect lift. Investing in elevators can mean long-term commitment to specific hardware. Leasing gives you the freedom to return it to the rental company for use of specialized lifts, such as those used for rough terrain.

Self propelled scissor lift

Self propelled scissor lift, also called electric scissor lift, powered by batteries, it can walk on its own.The device itself has the function of walking and steering drive, without manual traction and external power supply. It is flexible and convenient to move, making aerial work more convenient and fast, and is an ideal aerial work equipment for efficient and safe production of modern enterprises.

| Model | Plaform size(mm) | Heightm) | bearing load (kg) | Packing size(mm) | NW(KG) |

| MPGTJZ-6 | 2270*1130 | 6 | 450 | 2390*1160*2210 | 2100 |

| MPGTJZ-8 | 2270*1130 | 8 | 450 | 2390*1160*2340 | 2250 |

| MPGTJZ-10 | 2270*1130 | 10 | 320 | 2390*1160*2470 | 2550 |

| MPGTJZ-12 | 2270*1130 | 12 | 320 | 2390*1160*2600 | 2950 |

| MPGTJZ-14 | 2630*1130 | 14 | 227 | 2790*1400*2600 | 3300 |

| Model | Plaform size(mm) | Heightm) | bearing load (kg) | Packing size(mm) | NW(KG) |

| MPGTJZ-6 | 2270*1130 | 6 | 450 | 2390*1160*2210 | 2100 |

| MPGTJZ-8 | 2270*1130 | 8 | 450 | 2390*1160*2340 | 2250 |

| MPGTJZ-10 | 2270*1130 | 10 | 320 | 2390*1160*2470 | 2550 |

| MPGTJZ-12 | 2270*1130 | 12 | 320 | 2390*1160*2600 | 2950 |

| MPGTJZ-14 | 2630*1130 | 14 | 227 | 2790*1400*2600 | 3300 |

Make up of self propelled scissor lift

The DC electric drive wheel has a self-locking function, the brake is separated when the drive wheel is working, and it is automatically locked when it is not working. The self-propelled lifting platform consists of the following parts:

1, shear fork type main structure and telescopic workbench, as well as safety guardrail.

2, automatic walking DC electric drive wheel.

3, hydraulic system: pump station, oil cylinder, etc.

4, DC power supply, charger.

5, electric control box and operation box.

The use of automatic self propelled scissor lift

1. Safe operation process

The use of automatic small lifts needs to follow a certain safe operation process to ensure the safety of personnel and equipment. First of all, the operator should be familiar with the equipment instruction manual, and receive relevant training. During the operation, the following points should be noted:

(1) Ensure that there are no obstacles around the equipment, so as not to affect the normal operation of the lift.

(2) The operator should stand on the fixed platform of the lift, and should not stand on the lifting platform or suspended operation.

(3) During the lifting process, do not move or shake the lifting platform at will to avoid accidental injury.

(4) During use, attention should be paid to observing the operating status of the equipment, and if there is an anomaly, the use should be stopped in time and repaired.

2, use precautions

In addition to the safe operation process, the use of fully automatic small lifts also need to pay attention to the following points:

(1) Shall not be overloaded, should be used in accordance with the rated load of the equipment, so as not to damage the equipment or cause safety accidents.

(2) Regularly check the electrical system and hydraulic system of the equipment to ensure its normal operation.

(3) In the process of use, should avoid sudden power failure or power failure, so as not to cause personnel trapped or equipment damage.

(4) After the use, the power should be turned off in time and the equipment should be returned to the position.

Routine maintenance of automatic small lift

1, regular maintenance

The regular maintenance of automatic small lifts is crucial to the normal operation and extended service life of the equipment. Regular maintenance includes the following aspects:

(1) Clean the surface and interior of the equipment to prevent the accumulation of dust and debris, affecting the normal operation of the equipment.

(2) Check the electrical system and hydraulic system of the equipment to ensure its normal operation, and repair or replace the damaged parts in time if there is an anomaly.

(3) Lubricate the moving parts of the equipment to reduce friction and wear.

2. Troubleshooting

In the process of using a fully automatic small elevator, you may encounter some failures, such as equipment can not start, the lifting speed is slow. For these faults, the operator can perform the following troubleshooting:

(1) Check whether the power supply is normal, and ensure that the equipment is connected to the power supply and is in normal working condition.

(2) Check whether the hydraulic system is normal, such as whether the hydraulic oil is sufficient, whether the oil circuit is blocked, etc.

(3) Check whether the electrical system is normal, such as whether the wires are damaged, whether the wiring is loose, etc.

3, regular testing

In addition to regular maintenance and troubleshooting, automatic small lifts also need to be regularly tested to ensure the safety and performance of the equipment. Regular testing includes the following aspects:

(1) Test the load capacity of the equipment to ensure that the rated load of the equipment meets the requirements.

(2) Detect the lifting speed of the equipment to ensure that the lifting speed of the equipment meets the requirements.

(3) The safety device of the detection equipment, such as the limit switch, the fall prevention device, etc., to ensure its normal operation.

The use and daily maintenance of automatic small lifts are crucial to ensure the normal operation of the equipment and extend the service life. During use, the operator should follow the safe operation process and pay attention to the precautions for use. Regular maintenance, troubleshooting, and regular testing are critical steps to ensure equipment safety and performance. Through proper use and daily maintenance, fully automatic small lifts will bring more convenience and efficiency to our work and life.

CUSTOMER VISIT

这里是标题一h1占位文字

Customer visit

Customer visit

Customer visit

FACTORY WORKSHOP

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

FAQ

What services can we provide?

Why should you buy from us not from other suppliers?

What can you buy from us?

How can we guarantee quality?

Who are we?

RELATED PRODUCTS

GET A FREE QUOTE