Full automatic lifting platform

Classification :

Keywords : Convet Elevator Group

Mobile scissor lift is divided into towable scissor lift and self propelled scissor lift

Which are vertical lift platform for aerial work. The main feature is they can carry heavy load to heights, and they have extended table to increase working distance.

We are scissor lift manufacturers from China. Own a scissor lift factory. As a scissor lift supplier, we OEM and custom mobile scissor lift for you.

CONVET is Mobile platform lift manufacturer, supplying high quality mobile platform lift for you.

Electric scissor lifts have become an indispensable tool in modern industries, construction, maintenance, and various other sectors, providing a safe and efficient solution for working at height. In this article, we will explore the concept and features of electric scissor lifts, their classifications, applications, a comparison with manual scissor lifts, and the advantages of electric scissor lifts developed by CONVET Team. We will also present a summary of CONVET Team's key equipment models and specifications.

Concept and Features of Electric Scissor Lift

An electric scissor lift is a type of aerial work platform (AWP) that uses electric power to lift workers and materials to elevated areas. It features a “scissor” mechanism, consisting of crisscrossing supports that fold and unfold to raise or lower the platform. Electric scissor lifts are designed to be energy-efficient, easy to maneuver, and operate smoothly.

Key features of electric scissor lifts include:

· Quiet operation: They operate quietly, making them ideal for environments where noise is a concern.

· Environmentally friendly: Being powered by electricity, they produce no emissions and are suitable for indoor and outdoor use.

· Maneuverability: Many models come with controls that allow for precise movement in tight spaces.

· Safety features: These lifts are equipped with various safety mechanisms like anti-slip platforms, emergency lowering systems, and tilt sensors.

· Sustainability: The battery-powered design reduces fuel consumption and minimizes operational costs in the long term.

Self propelled scissor lift

Self propelled scissor lift, also called electric scissor lift, powered by batteries, it can walk on its own.The device itself has the function of walking and steering drive, without manual traction and external power supply. It is flexible and convenient to move, making aerial work more convenient and fast, and is an ideal aerial work equipment for efficient and safe production of modern enterprises.

| Model | Plaform size(mm) | Heightm) | bearing load (kg) | Packing size(mm) | NW(KG) |

| MPGTJZ-6 | 2270*1130 | 6 | 450 | 2390*1160*2210 | 2100 |

| MPGTJZ-8 | 2270*1130 | 8 | 450 | 2390*1160*2340 | 2250 |

| MPGTJZ-10 | 2270*1130 | 10 | 320 | 2390*1160*2470 | 2550 |

| MPGTJZ-12 | 2270*1130 | 12 | 320 | 2390*1160*2600 | 2950 |

| MPGTJZ-14 | 2630*1130 | 14 | 227 | 2790*1400*2600 | 3300 |

| Model | Plaform size(mm) | Heightm) | bearing load (kg) | Packing size(mm) | NW(KG) |

| MPGTJZ-6 | 2270*1130 | 6 | 450 | 2390*1160*2210 | 2100 |

| MPGTJZ-8 | 2270*1130 | 8 | 450 | 2390*1160*2340 | 2250 |

| MPGTJZ-10 | 2270*1130 | 10 | 320 | 2390*1160*2470 | 2550 |

| MPGTJZ-12 | 2270*1130 | 12 | 320 | 2390*1160*2600 | 2950 |

| MPGTJZ-14 | 2630*1130 | 14 | 227 | 2790*1400*2600 | 3300 |

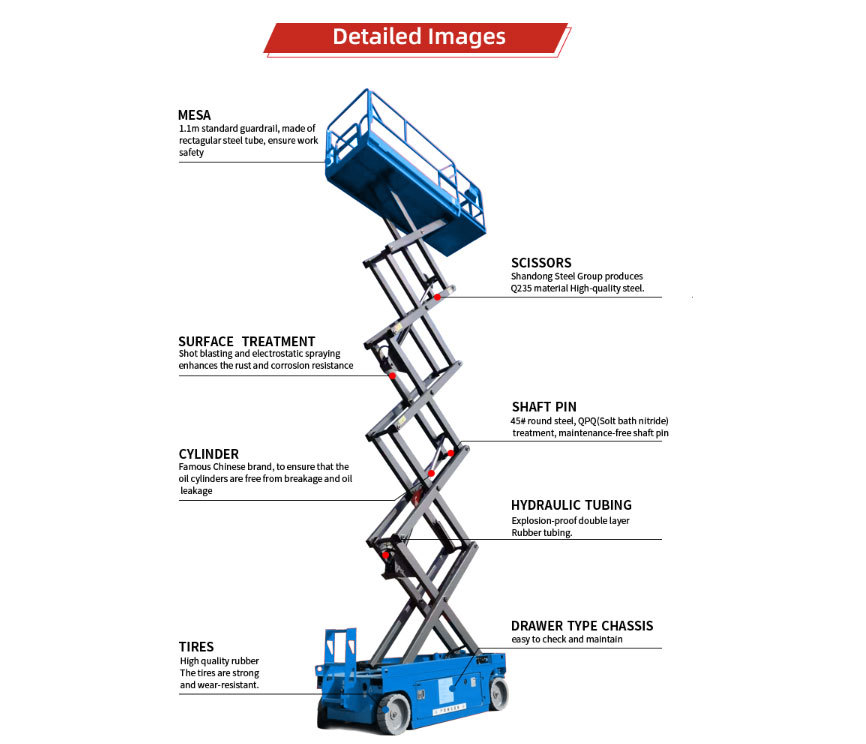

Make up of self propelled scissor lift

The DC electric drive wheel has a self-locking function, the brake is separated when the drive wheel is working, and it is automatically locked when it is not working. The self-propelled lifting platform consists of the following parts:

1, shear fork type main structure and telescopic workbench, as well as safety guardrail.

2, automatic walking DC electric drive wheel.

3, hydraulic system: pump station, oil cylinder, etc.

4, DC power supply, charger.

5, electric control box and operation box.

The use of automatic self propelled scissor lift

1. Safe operation process

The use of automatic small lifts needs to follow a certain safe operation process to ensure the safety of personnel and equipment. First of all, the operator should be familiar with the equipment instruction manual, and receive relevant training. During the operation, the following points should be noted:

(1) Ensure that there are no obstacles around the equipment, so as not to affect the normal operation of the lift.

(2) The operator should stand on the fixed platform of the lift, and should not stand on the lifting platform or suspended operation.

(3) During the lifting process, do not move or shake the lifting platform at will to avoid accidental injury.

(4) During use, attention should be paid to observing the operating status of the equipment, and if there is an anomaly, the use should be stopped in time and repaired.

2, use precautions

In addition to the safe operation process, the use of fully automatic small lifts also need to pay attention to the following points:

(1) Shall not be overloaded, should be used in accordance with the rated load of the equipment, so as not to damage the equipment or cause safety accidents.

(2) Regularly check the electrical system and hydraulic system of the equipment to ensure its normal operation.

(3) In the process of use, should avoid sudden power failure or power failure, so as not to cause personnel trapped or equipment damage.

(4) After the use, the power should be turned off in time and the equipment should be returned to the position.

Routine maintenance of automatic small lift

1, regular maintenance

The regular maintenance of automatic small lifts is crucial to the normal operation and extended service life of the equipment. Regular maintenance includes the following aspects:

(1) Clean the surface and interior of the equipment to prevent the accumulation of dust and debris, affecting the normal operation of the equipment.

(2) Check the electrical system and hydraulic system of the equipment to ensure its normal operation, and repair or replace the damaged parts in time if there is an anomaly.

(3) Lubricate the moving parts of the equipment to reduce friction and wear.

2. Troubleshooting

In the process of using a fully automatic small elevator, you may encounter some failures, such as equipment can not start, the lifting speed is slow. For these faults, the operator can perform the following troubleshooting:

(1) Check whether the power supply is normal, and ensure that the equipment is connected to the power supply and is in normal working condition.

(2) Check whether the hydraulic system is normal, such as whether the hydraulic oil is sufficient, whether the oil circuit is blocked, etc.

(3) Check whether the electrical system is normal, such as whether the wires are damaged, whether the wiring is loose, etc.

3, regular testing

In addition to regular maintenance and troubleshooting, automatic small lifts also need to be regularly tested to ensure the safety and performance of the equipment. Regular testing includes the following aspects:

(1) Test the load capacity of the equipment to ensure that the rated load of the equipment meets the requirements.

(2) Detect the lifting speed of the equipment to ensure that the lifting speed of the equipment meets the requirements.

(3) The safety device of the detection equipment, such as the limit switch, the fall prevention device, etc., to ensure its normal operation.

The use and daily maintenance of automatic small lifts are crucial to ensure the normal operation of the equipment and extend the service life. During use, the operator should follow the safe operation process and pay attention to the precautions for use. Regular maintenance, troubleshooting, and regular testing are critical steps to ensure equipment safety and performance. Through proper use and daily maintenance, fully automatic small lifts will bring more convenience and efficiency to our work and life.

CUSTOMER VISIT

这里是标题一h1占位文字

Customer visit

Customer visit

Customer visit

FACTORY WORKSHOP

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

Factory Workshop

FAQ

What services can we provide?

Why should you buy from us not from other suppliers?

What can you buy from us?

How can we guarantee quality?

Who are we?

RELATED PRODUCTS

GET A FREE QUOTE